Bare board, Package, Populated Board Testing

Products Categories

ATE Concept The Power to Connect

Continuing to create new solutions together

The power to connect that Hioki’s printed circuit board testing systems deliver is the power to connect to the future. The ability to continue to support this rich and satisfying lifestyle together with customers is a small part of what testing systems can do.

At Hioki, we strive on a daily basis to improve the contact performance–the power to connect with circuit boards–that is the lifeblood of electrical testing and to seek out the true potential of that capability. This is the path that we follow.

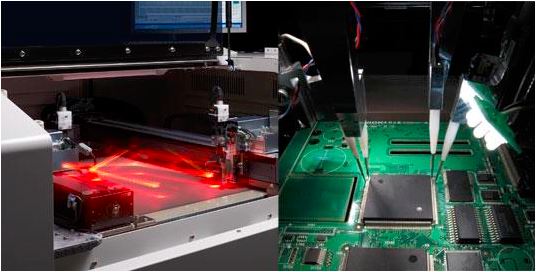

FLYING PROBE TESTER FA1816

Significantly lower testing costs

while maintaining high-speed performance

• High-speed pattern testing using the capacitive measurement method

• Reduce probe marks in combination with the latest probes

• Significantly improved operability

FLYING PROBE TESTER FA1817

Detect Latent Failures in High Density Substrates

Without Fail

• Optimization of probe movement reduces inspection time by up to 20%

• Reduce probe marks in combination with the latest probes

• Fault analysis using newly developed “Process Analyzer”

FLYING PROBE TESTER FA1811

Meeting Ever Increasing Demands for Greater Analytical

Power,

Faster Testing Speeds and Reduced Costs

• Achieve both high precision contact and high-speed probing in a space of 10 μm.

• Double test method delivers an operation rate of 100%.

• Full-net insulation continuity test using resistance: x10 max. speed*

• High-speed test using capacitance: x2 max. speed*

(* Compared to the double-sided 4-arm FLYING PROBE TESTER)

FLYING PROBE TESTER FA1283

Complete Electrical Testing of High-Function Boards with

a Single Unit

• Achieves square 15 μm high precision contacts and high speed probing

• Max.100 points/s ultra-high speed inspection

• Inspection is possible from general bare board to fine and high density substrates such as flexible substrate and CSP.

• In addition to capacitance measurement, measurement functions for component built-in boards such as diodes are also complete

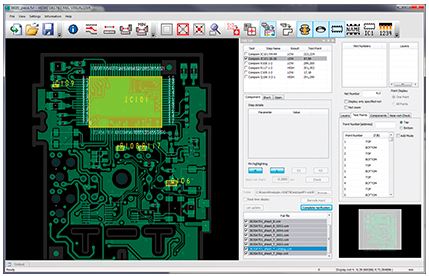

FAIL VISUALIZER UA1782

Robust Support for Repair Work Using Simple

Operations and Assistive Functionality

• Visualize test results from flying-probe testers

• Pinpoint components and patterns from test result files

• Display the probing positions of test fixtures or test heads for both ICT and bare board testers

• Search for components and nets on device embedded substrates

IN-CIRCUIT TESTER FA1220-02

Batch Testing System for Improved Populated

Circuit Board Productivity

• Slide-in mechanism simplifies installation and removal of test fixtures, reducing man-hours and workload.

• Extension range of options that reduces setup man-hours and boosts productivity.

• Numerous measurement parameters and detecting defects for a wide variety of inspections.

• Productivity, quality, and safety.

• Data creation support functionality: ATG function.

IN-CIRCUIT TESTER FA1220-11

Boost Productivity of Populated Circuit Board Testing

with the Inline Automatic Testing System

• Installation area about 23% smaller than the previous model. Offers new flexibility for production line layout by saving space.

• Extension range of options that reduces setup man-hours and boosts productivity.

• Numerous measurement parameters and detecting defects for a wide variety of inspections

• Safeguard people, products, and lines with many safety features.

• Data creation support functionality: ATG function.

IN-CIRCUIT TESTER FA1220

Embed into Existing Equipment to Conduct Functional Tests of

Individual Electronic Circuit Board Components or While Mounted on PCBs

• Functionality has been consolidated in a single, desktop tower that can be easily embedded in existing equipment

• Extensive function testing

• Electrolytic capacitor and IC reverse insertion detection

• Macro-testing function to increase test efficiency

• Four-terminal low-resistance measurement for stable measurement of low resistance

SHORT-OPEN TESTER FA1221

Multichannel short/open tester that can be embedded

in existing test equipment

• Functionality has been consolidated in a single, desktop tower that can be easily embedded in existing equipment

• Specifically designed for short/open testing

• Four-terminal low-resistance measurement for stable measurement of low resistance

FLYING PROBE TESTER FA1240-6x

Electrical Testing Verifies Correct Mounting

Populated Board Testing System

• Quickly complete programs that take into account component height

• Automatically calculate arm interference (when used with the UA1780)

• Designed to improve probe replaceability, dramatically reducing system downtime caused by probe replacement

• High-speed testing at up to 0.025 sec./step

• Detect IC lead float and pseudo-contact states

• Support for active testing (optional feature)

• High-precision probing

• Large testing area of 510 × 460 mm (FA1240-61)

• Standard transport capability

• Automatic alignment function and simple visual test function

CE Compliant model: FA1241-61

IN-CIRCUIT HiTESTER 1220

High Performance Populated Board Testing with

Expansion Capabilities

• Extensive test functionality in a single tabletop box (1220-50)

• Detection of electrolytic capacitor and IC reverse insertion (optional feature)

• Macro testing for increasing test efficiency

• Extensive range of system configurations

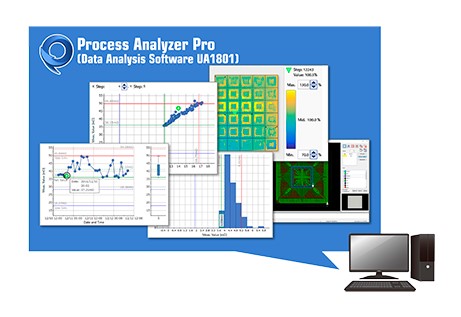

Data Analysis Software for Detecting Latent

Defects on PASS Boards

• Perform statistical analysis using the latest AI technologies

• Detect significant points that can cause latent defects

• Provide feedback to improve quality in board production and design processes

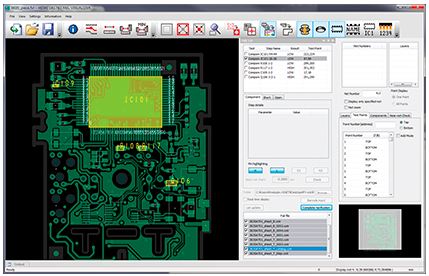

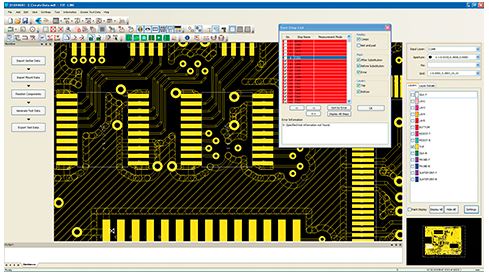

FEB-LINE INSPECTION DATA CREATION SYSTEM UA1781

FLYING PROBE TEST 1/2 Data Generation Time With

New Platform

• Easily generate test points even on the inner layer for cavity structures (one-point test-point generation)

• Expanded touch panel functions for printed boards (Optional E7001)

• Support for built-in component boards

• High-precision relay-point deletion functionality that reliably delete only the unnecessary relay-points

FAIL VISUALIZER UA1782

Robust Support for Repair Work Using Simple

Operations and Assistive Functionality

• Visualize test results from flying-probe testers

• Pinpoint components and patterns from test result files

• Display the probing positions of test fixtures or test heads for both ICT and bare board testers

• Search for components and nets on device embedded substrates

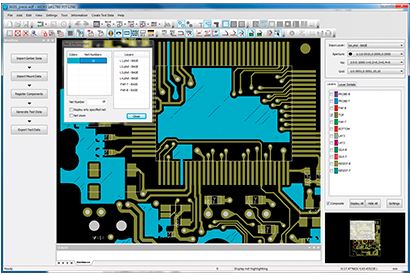

FIT-LINE INSPECTION DATA CREATION SYSTEM UA1780

Data Creation Software for Populated Board Testing

• No need for camera-based teaching

• No need to visually trace patterns under components

• Easy generation of high-quality test data without boards

• Support for the new FA1240 data format